Coating Solutions

Comprehensive UV Coating & Lamination Solutions

Core Challenges & Solutions :

Challenge ① Weak Adhesion

Digital prints coating get off → UV lamination machine with corona treatment achieves 4B adhesion grade (85% less peeling)

Challenge ② Poor Protection

"Outdoor ads yellow in 1 year" → UV roller coating machine blocks 99% UV380 (5-year color stability ΔE<1.5)

Challenge ③ Low Efficiency

"complicated process,with defect and waste sometimes" → PRO UV coating system runs 3200 sheets/hr (40% faster and stable)

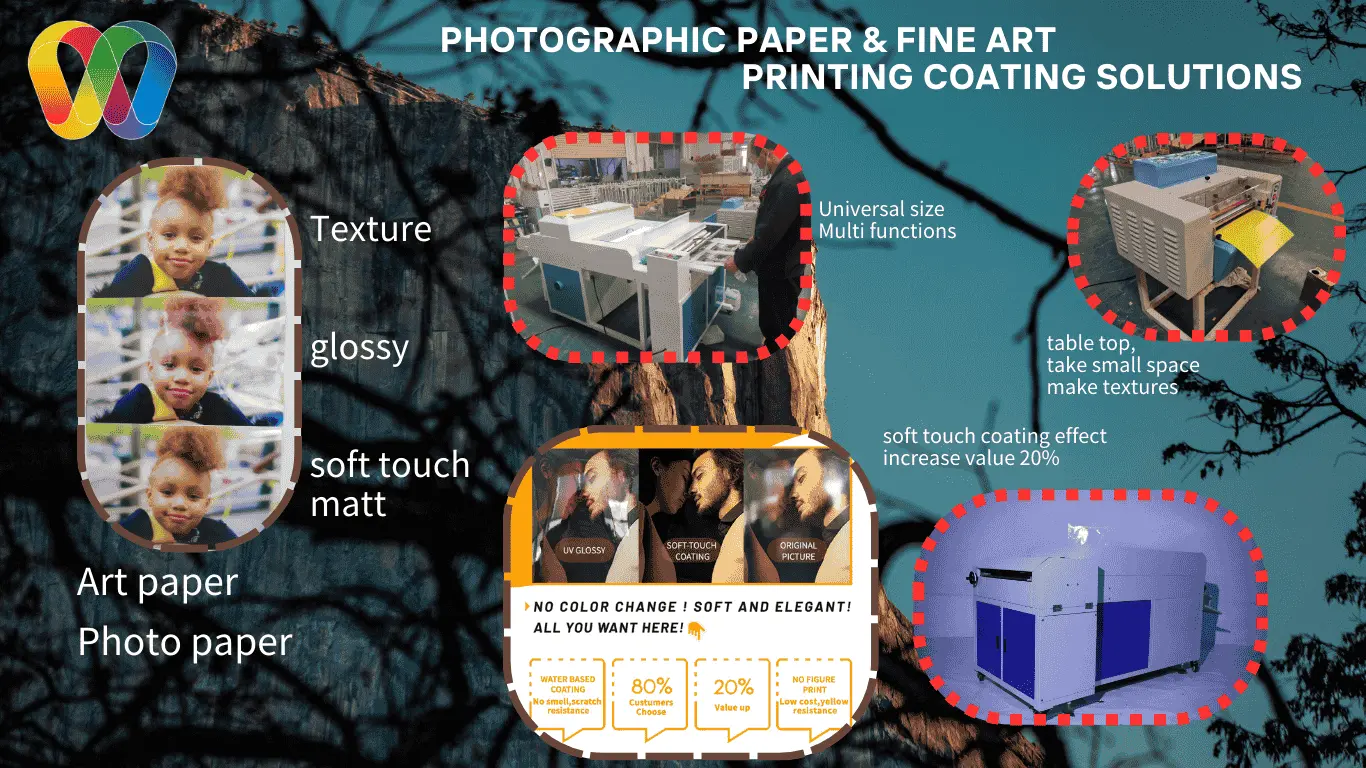

High-End Photographic Paper & Fine Art Printing Coating Solutions

Industries:

High-end photographic paper, fine art photography, museum-grade prints, luxury wedding albums, limited edition art exhibits

Customer Needs:

Long-term preservation with fade resistance

Exquisite tactile feel, anti-fingerprint, and multiple finish options (gloss, matte, and velvet-like finishes)

Compact production footprint

Solution:

Utilize dual-sided lamination with PE resin and silicon solution ink absorption layers

Options include high-gloss UV coating, patterned UV lamination, matte finishes, or premium Korean velvet (Han-ram) texture layers

Proven longevity with accelerated aging tests extending print life up to 20 years, while enhancing product premium value by up to 30%

Recommended Equipment:

350 Desktop UV lamination machine

480 and 650 UV coating machine

Digital Printing UV Lamination Solutions

Industries:

Digital printing, quick print shops, corporate annual reports, personalized wedding invitations

Customer Needs:

Enhanced toner adhesion

Reduced small-batch production costs

Solution:

Combine corona (electrical) pretreatment with UV lamination techniques

Single-pass application of matte and high-gloss layers using high-speed UV coating machines

Achieve up to 5H pencil hardness with reduced per-sheet cost by 60% compared to traditional methods

Recommended Equipment:

QH corona treatment system

SQH650 high-speed UV lamination machine

Offset Printing & Packaging Box UV Curing Solutions

Industries:

Commercial printing, promotional brochures, luxury packaging boxes, cosmetics inserts, high-end brand catalogs

Customer Needs:

High gloss, abrasion resistance, moisture protection, and high-speed production

Solution:

Integrated inline UV coating with rapid curing technology

Offset printing combined with UV curing machines ensures high gloss (up to 95GU mirror finish) and exceptional production speeds (up to 18 m/min)

Recommended Equipment:

SQH650 UV coating machine

PROUV650 UV curing equipment

Large Format Advertising & Coating for Indoor/Outdoor Applications

Industries:

Large banners, vinyl advertising, PVC panels, corrugated boards, bus wraps, mall installations, outdoor lightbox ads

Customer Needs:

Waterproof, UV-resistant, and weatherproof finishes (3+ years durability)

Solution:

Roll-to-roll UV lamination processes with special anti-UV light oil formulations

Options for board, corrugated, and vinyl substrates, validated by QUV 3000-hour accelerated aging tests (equivalent to 5 years outdoor performance)

Recommended Equipment:

ROL1350 UV coating machine

ROL1600 UV coating machine

Roll-to-Roll Label UV Lamination Solutions

Industries:

Adhesive labels, barcode labels, pharmaceutical labels, food expiry labels, logistics tracking labels

Customer Needs:

Resistance to low temperatures, oil-proof performance, and long-lasting clarity

Solution:

Continuous roll-to-roll UV lamination ensuring reliable adhesion even at -30°C

Withstands repeated oil wiping (30 cycles) without degradation

SEO Keywords Integrated:

UV coating machine for label

UV lamination machine for labels

UV coater for adhesive labels

Recommended Equipment:

LBL-350 dedicated roll-to-roll UV lamination equipment

Ceramic, Marble, and Crystal Surface UV Coating Solutions

Industries:

Ceramic tiles, marble, glass, wooden panels for hotel lobbies, luxury furniture, commercial wall panels

Customer Needs:

Ultra-high hardness, scratch resistance, and artistic texture

Solution:

Crystal glaze coatings combined with 3D embossing techniques

Achieves a Mohs hardness of up to 6 (comparable to quartz) with customizable embossing depths ranging from 0.1 to 2 mm

SEO Keywords Integrated:

UV coating machine for tiles

UV lamination machine for marble

UV coater for decorative surfaces

Recommended Equipment:

800mm large-scale roll coater

Food Packaging & Sterile UV Lamination Solutions

Industries:

Food boxes, packaging bags, fast-food containers, frozen food packaging, coffee cup linings, and Blister Coating for pharmaceuticals and electronics

Customer Needs:

Non-toxic, FDA-compliant, leak-proof, and high-temperature resistance (up to 110°C)

Low water vapor transmission (below 0.1 g/m²·day)

Solution:

Water-based UV lamination with inline quality monitoring

For Blister Coating, suitable for medical devices and moisture-sensitive electronic components

Options using biodegradable PHA/PLA films for eco-friendly packaging solutions

SEO Keywords Integrated:

UV coating machine for food packaging

UV lamination machine for sterile packaging

Eco-friendly UV coater

Recommended Equipment:

PRO series sterile UV lamination machines

Blister Coating Solutions for Consumer Packaging

Industries:

Consumer packaging for items like toothpaste boxes, battery boxes, and other similar products

Pharmaceutical packaging and electronic product blister packs

Customer Needs:

Superior protection against moisture and oxygen to maintain product integrity

Enhanced visual appeal with high clarity and precise finish

Compliance with stringent quality and safety standards for consumer goods

Solution:

Advanced blister coating technology integrating UV curing processes to achieve a high-quality, consistent finish

Specifically optimized for consumer packaging applications including toothpaste boxes, battery boxes, and other related items

Provides excellent barrier properties that protect products from environmental factors such as humidity and contaminants

Rapid processing speeds suitable for high-volume production while maintaining uniformity across various substrates

SEO Keywords Integrated:

UV blister coating

Blister coater for toothpaste boxes

Blister coating machine for battery boxes

Consumer packaging UV coater

Recommended Equipment:

Specialized blister coating machines designed for high-speed, inline production

Equipment options tailored for consumer packaging applications, ensuring reliable performance for both toothpaste boxes and battery boxes

Our comprehensive UV coating and lamination solutions cater to a wide range of industries, ensuring enhanced durability, superior aesthetics, and cost efficiency. Whether you are involved in high-end photography, digital printing, packaging, large format advertising, label production, decorative surfaces, food packaging, or consumer packaging like toothpaste and battery boxes with blister coating solutions, our range of UV coating machines, UV lamination machines, and UV coaters are engineered to meet your specific needs.

Why Choose Double100?

Double100 stands out with its deep expertise in the lamination industry, offering globally leading lamination solutions developed over many years. We combine advanced equipment and innovative technology to ensure efficient, eco-friendly, and high-quality lamination results. Our tailored solutions are designed to meet diverse industry needs, providing exclusive lamination processes that adjust coating thickness, gloss, and tactile effects to suit various printing techniques and material properties—whether for photographic paper, PVC, cardboard, or metal plates.

Our commitment to energy-saving and cost reduction is reflected in our optimized lamination processes and equipment designs. With lower energy consumption and compact footprint, our systems help reduce overall operating costs, giving you a competitive edge in the market.

Double100 offers a comprehensive, one-stop service chain, including:

Pre-Solution Consultation: We thoroughly understand your needs and provide detailed market research along with custom technical proposals.

Technical Customization & Equipment Supply: We recommend the optimal equipment combinations and process parameters based on your specific application scenarios, supporting everything from pilot production to full-scale manufacturing.

After-Sales Technical Support: With global service coverage and regular training, we ensure that your equipment operates at peak efficiency while responding quickly to your requirements.

Choose Double100 for unmatched professionalism, technological innovation, and comprehensive support that empowers your business to excel in today’s competitive market.